- 10 HP spindle motor infinitely variable speed, #50 taper spindle, 24” x 87” hardened and ground table top

- Saddle and base with hardened and ground square (box) ways

- Precision ACME screws in X, Y, & Z axes

- X, Y, & Z axes driven by AC motor

- Precision bored and ground milling head, with super precision ABEC-7 bearings

- Meehanite® casting, with built in coolant reservoir in machine base

- Coolant system and chip tray

- Centralized automatic lubrication, with metered check-valves

- Precise angular contact bearings spindle

- Precision manufactured from SCM21 alloy steel, heat treated and precision ground spindle

- Hardened and precision ground for quiet running gears

- High torque servo motor X-axis feed

- Choice of Fanuc or Mitsubishi CNC controller

- Hardened, precision ground, and Turcite-B coated sideways for maximum wear resistance

- Convertible into CNC controlled system

19.7 ” x 75″ KENT USA JY-VH650 COMBINATION HORIZONTAL & VERTICAL SPINDLE MILL – NEW

PRODUCT FEATURES

OPTIONAL ACCESSORIES

- Dro System

- Air Power Drawbar (Per Spindle)

- Angle-Lock Vice

- Rotary Table (Vertical and Horizontal)

- Clamping Kit

- Chuck System

- Rustlick Coolant (1 Gal, Mixes 1:30)

- Table Size

- Table Travel (X-Axis)

- Saddle Travel (Y-Axis)

- Knee Travel (Z-Axis)

- T-Slot

- X, Y, Z Feedrate

- X, Y, Z Rapid Feedrate

- Spindle Motor

- Vertical Spindle Speed

- Vertical Spindle Taper

- Spindle Nose to Table

- Spindle Center to Column

- Horizontal Spindle Speed

- Horizontal Spindle Taper

- Spindle Center to Table

- Spindle Nose to Rear

- Maximum Work Load

- Machine Net Weight

- Shipping Weight

- Dimensions

JY-VH650

- 24″ x 87″

- 67″

- 41.3″

- 37.4″

- 0.98″ x 0.2″ x 4.92″

- 1.2″/min -110″/min

- 110″/min

- 10 HP

- 45 – 1500 RPM (variable)

- NT-50

- 0 – 30″

- 26″

- 45 – 1500 RPM (variable)

- NT-50

- -.39 – 31.88″

- 11.6″

- 4400 lbs

- 16500 lbs

- 18700 lbs

- 139″ x 138″ x 121

- “

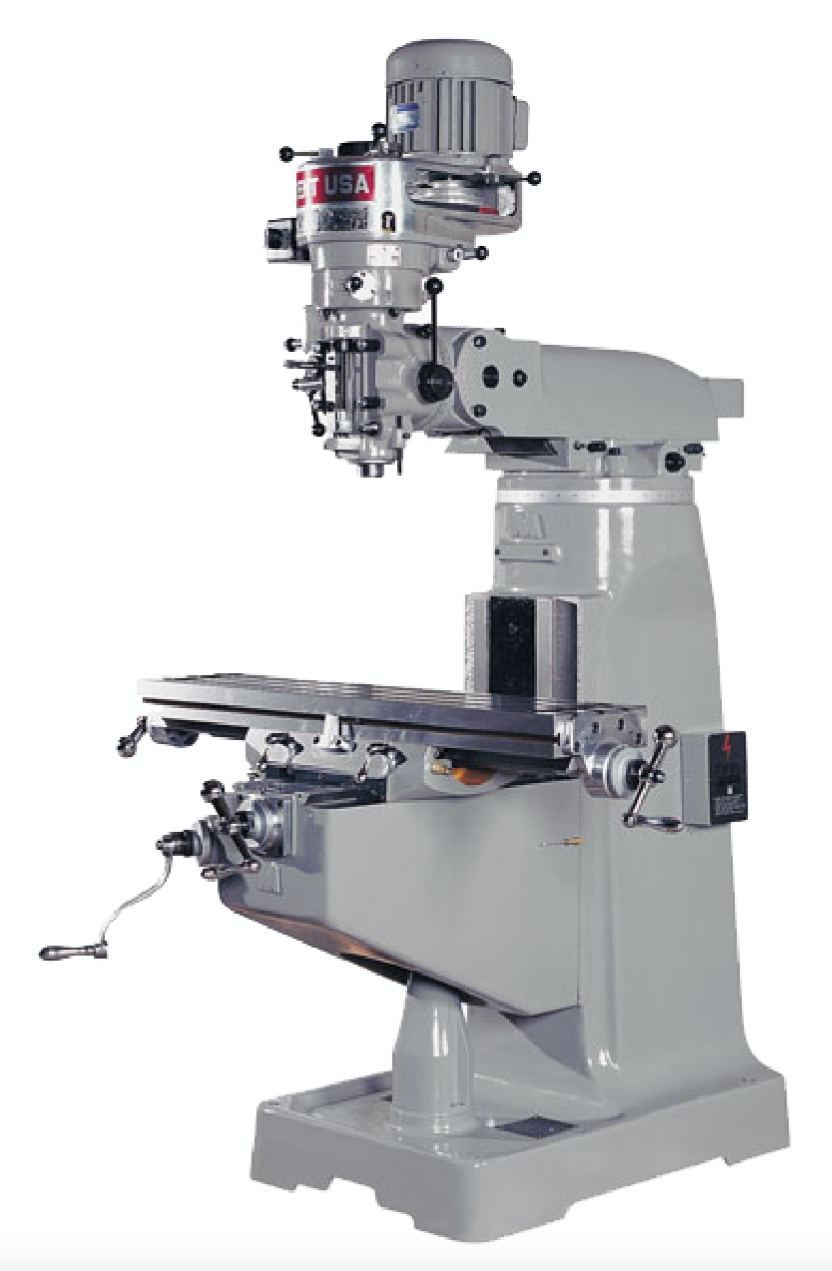

9" x 42" KENT USA KTM-3S MANUAL KNEE MILL - NEW

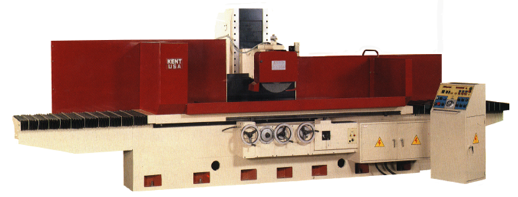

9" x 42" KENT USA KTM-3S MANUAL KNEE MILL - NEW  24″ x 80″ KENT USA SGS-2480 AHD AUTOMATIC SURFACE GRINDER - NEW

24″ x 80″ KENT USA SGS-2480 AHD AUTOMATIC SURFACE GRINDER - NEW  10" x 50" KENT USA KTM-5AVKF MANUAL KNEE MILL - NEW

10" x 50" KENT USA KTM-5AVKF MANUAL KNEE MILL - NEW  16" x 36" SHIGIYA SEIKI MODEL GUA-41-100 UNIVERSAL OD/ID CYLINDRICAL GRINDER

16" x 36" SHIGIYA SEIKI MODEL GUA-41-100 UNIVERSAL OD/ID CYLINDRICAL GRINDER