TOS MODEL OFA 32A AUTOMATIC CYCLING GEAR HOBBING MACHINE

Serial No. 45-483 New 1995

The OFA 32A Gear Hobber is designed to hob spur gears with straight or helical teeth, sprocket wheels, worm wheels in radial hobbing method, spline shafts and other types of profiled components in the gear generating method.

The machine is suitable for the single piece or batch construction.

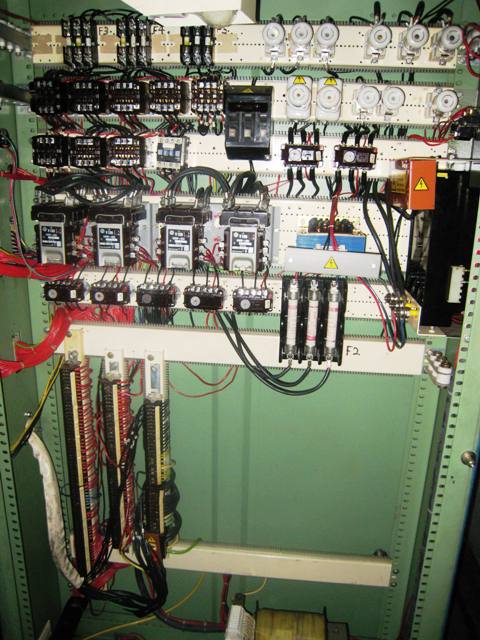

Motor Driven With AC Motor and Controls, Motor Driven Hydraulic and Coolant Systems.

EQUIPPED WITH

Automatic Work Loading Attachment, Helical Gear Attachment, Tangential-Drive Head Which Will Allow The Machine To Produce Work Wheels In The Tangential Method. Hydraulic Clamping Cylinder. Gear Blank Clamping Attachment For The Hydraulic Clamping Cylinder. Large Quantity of Change Gears And Work Holding Fixtures. Magnetic Swarf Conveyor and Speed Pulleys.

SPECIFICATIONS

Max Gear Diameter 320mm (12.6″)

Max. Module To Be Hobbed 7mm (3.6 DP)

Hob Head Travel 250mm (9.8″)

Distance Hob Axis To Table Axis

Min. 40mm (1.6″)

Max. 300mm (11.8″)

Max. Helical Angle Of Gear Teeth ±45°

Max. Diameter Of Hob 150mm (5.9″)

Max. Length Of Hob 200mm (7.8″)

Hob Speeds In Steps (17) 71-450 RPM

Diameter Of Work Table 300mm (11.8″)

Bore In Work Table 80mm (3.2″)

Axial Feeds 1-220mm/min

Radial Feeds 0.5-25mm/min

Tangetial Feeds 0.26-50mm/min

Rapid Traverse

Axial 560mm/min (22 IPM)

Radial 300mm/min (11.8 IPM)

Tangential 60/30 mm/min

Approx Dimensions 2.5M L-R x 2.4M F-B( 99.2″LR x 94.1″FB)

Approx Height 1.8M (71.65″)

Approx Weight 6,200KG (14,000 Lbs)

MAKINO MODEL U1310 TRAVELING COLUMN WIRE EDM MACHINE

MAKINO MODEL U1310 TRAVELING COLUMN WIRE EDM MACHINE  6' x 1/4" CINCINNATI 1806-R MECHANICAL SHEAR

6' x 1/4" CINCINNATI 1806-R MECHANICAL SHEAR  MAKINO MODEL U1310 TRAVELING COLUMN WIRE EDM MACHINE

MAKINO MODEL U1310 TRAVELING COLUMN WIRE EDM MACHINE