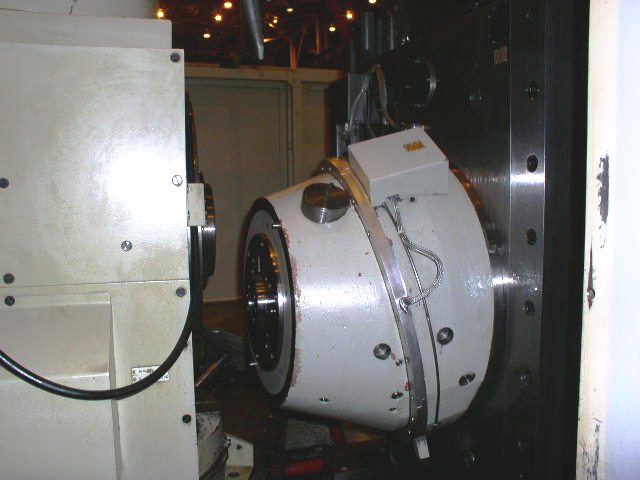

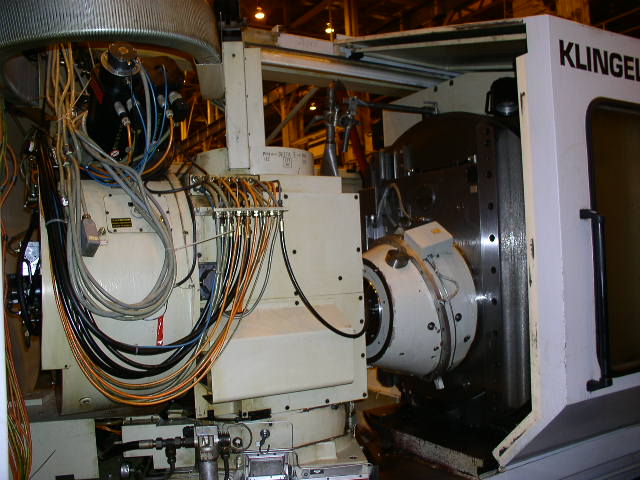

Klingelnberg Oerlikon S35 10 Axis Spiral Beval and Hypoid Gear Cutting Machine

Serial No. 380 New 1993

The Klingelnberg Oerlikon S-35 is especially suited for medium to large series production of spiral bevel and hypoid gears with working diameters up to 600mm for the automotive industry. All axis of the S-35 are CNC controlled. This machine was designed to have extremely high dependability and precision.

The S-3 operated with both the continuous and single indexing methods, thus enabling the user to produce gear sets using the most common Oerlikon and Gleason methods.

The S-35 will Face Hob with Klingelnberg/Oerlikon FS Cutter Bodies and Face Mill with Gleason Five Cut or Completing Index Methods. The Cutter Spindle Oerlikon Taper Adapter will come off to reveal the Gleason Cutter Taper Adapter inside the Oerlikon Nose.

SPECIFICATIONS:

Max Workpiece Dia. ………… 23.6″ (600mm)

Smallest Normal Module …….. 0.137″ (3.5mm)

Largest Normal Module ……… 0.393″ (10mm)

Max Tooth Width …………… 3.93″ (100mm)

Smallest Transmission Ratio … 1:1

Largest Transmission Ratio …. 1:10

Spiral Angle (Degrees) …….. 0-60

CUTTER HEAD SPINDLE:

Oerlikon Short Taper 1:4 …… 0-5.118″ (0-130mm)

Spindle Speeds (Inf. Var.) …. 30-350 min-1

Spindle Tilt (Degrees) …….. 0-35

Eccentricity ……………… 0-10.82″ (0-275mm)

Cutter Head Radius ………… 3.46″-7.12″ (88-180mm)

WORKPIECE SPINDLE

Oerlikon Outside Taper 1:4 …. 0-8.85″ (0-225mm)

Inside Taper No. 39, 1:19,692 …….. 6″ (152mm)

Max Spindle Speed …………. 0-160 min-1

Bore …………………….. 0-6.29″ (0-160mm)

Axial Offset ……………… +/-2.36″ (+/- 60mm)

Swivel Range (Degrees)……… -7 up to 90

FEEDS:

Generating Feed (Inf. Var.) … 40 Deg./Second

EQUIPPED WITH:

Schleicher (Siemens) 10-Axis CNC w/ RS-232

11″ Magnetic Chip Conveyor

Bosch Drives

Continuous & Single Indexing Methods

AC Motors & Controls

100 KVA Transformer

Chiller

Mist Collector

McLean Air Conditioner Unit

VIDEO LINK: http://www.youtube.com/watch?v=E-aug4duVf4

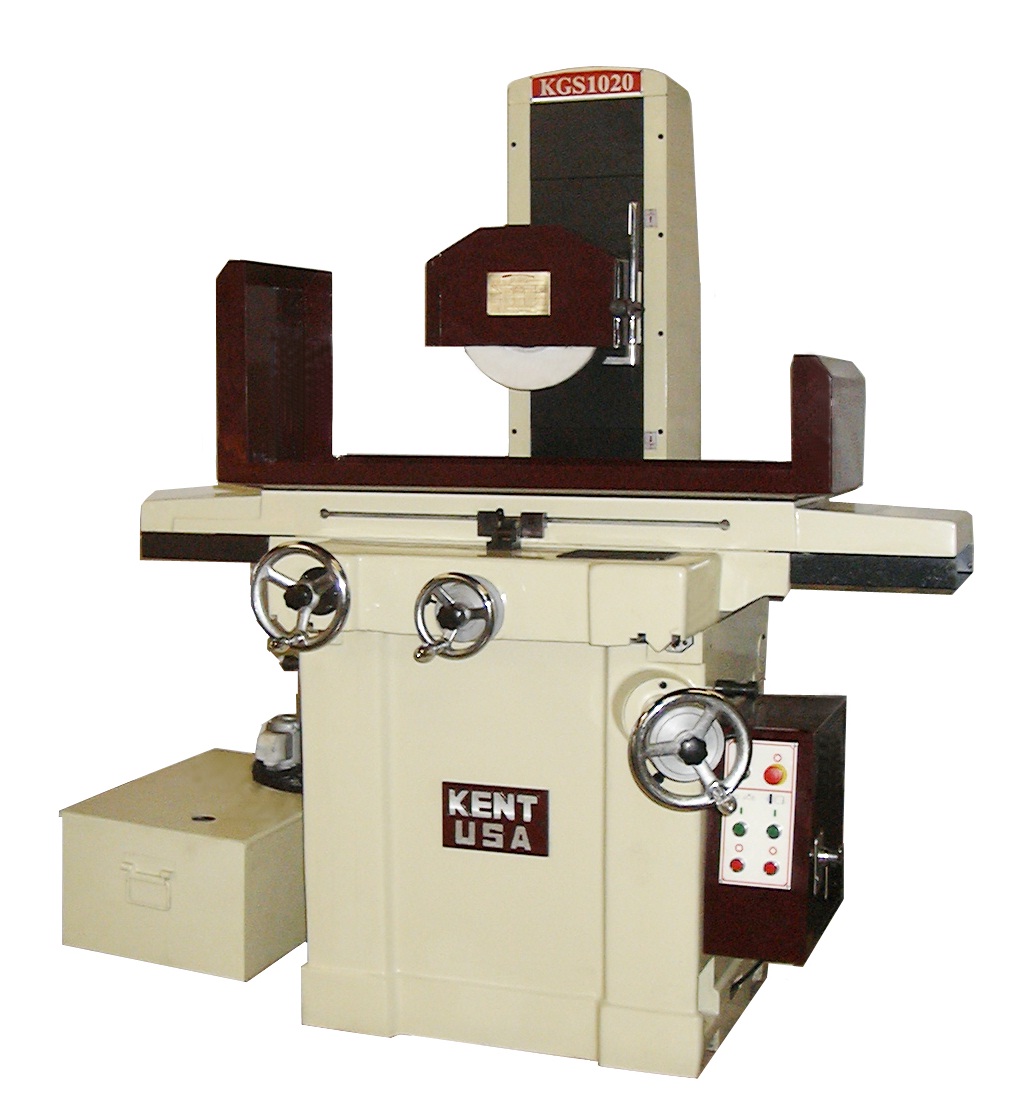

10" x 20" KENT USA KGS-1020 MANUAL HAND FEED GRINDER - NEW

10" x 20" KENT USA KGS-1020 MANUAL HAND FEED GRINDER - NEW  48" X 0.135" X 30,000 LBS RED BUD MODEL FMBD 9-48-84 LOOP DESIGN CUT TO LENGTH LINE

48" X 0.135" X 30,000 LBS RED BUD MODEL FMBD 9-48-84 LOOP DESIGN CUT TO LENGTH LINE