KENT USA KLR-300 CNC TURNING CENTER – NEW

The KENT USA KLR-300 series CNC slant bed lathe combines proven machine design with advance technology in control and manufacturing. Reliability and stability make these a favorite among demanding job shops and in-house productions alike. The heavy duty turret and rigid machine body structure enable higher turning efficiency with better finish and longer tool life – resulting in greater productivity and profitability all around. Upgrade your global competitiveness today

PRODUCT HIGHLIGHTS

- High power spindle motor

- Large bar capacity

- Large maximum turning diameter

- High speed / high accuracy heavy duty 12 station turret

- Fully enclosed way covers and enclosure

- Induction hardened and precision ground box ways

- Certified Meehanite machine casting for superior dampening and stability

- High grade C3 precision ball screws and pretension for enhanced precisio

- Auto lubrication system metered check valves and piston distributor

- Programmable tail stock body and quill

STANDARD ACCESSORIES

- Fanuc 0i-T CNC control with 8.4” color LCD

- Fanuc i-Series high torque spindle and axis motor with digital drive system

- Fanuc Absolute Encoders – machine axis start up “Home” sequence not required

- Fanuc Auto-Measure System (X and Z)

- Fanuc Macro-B and High Speed Skip Function

- Fanuc USB, PCMCIA, Ethernet and RS-232 ports

- Fanuc Manual Guide 0i – computer assist programming

- Fanuc 400 registered part program numbers and 640M part program memory

- Swivel-Out control panel

- Heat exchanger for electrical cabinet

- Hydraulic power supply unit

- Flood coolant system (4 bar)

- Chain type chip conveyor and chip cart

- Full enclosure and way covers

- Automatic lubrication system

- 3 color stack indicator light

- 12 station heavy duty high precision turret

- Programmable tail stock body and quill

- Standard soft jaws 3 sets + hard jaws 1 set

- Induction hardened and precision ground box ways

- 30º slant bed with one piece Meehanite® casting

- C-3 grade high precision ball screws

- Facing tool holder (R/H) 25×25 mm 1 set

- Facing tool holder (L/H) 25×25 mm 1 set

- Boring bar holder ø40 mm 3 sets with 10/12/16/20/25/32 mm sockets

- U-drill holder ø40 mm 1 set with 20/25/32 mm sockets

- Drilling socket ø40 mm 1 set MT 1/2/3

- Operator and Maintenance/Parts manuals

- Standard equipment and accessories

- Fanuc 0i-T cnc control with 8.4” color LCD

- 10” 3-jaw hydraulic chuck with 75 mm bar capacity

- 12 station hydraulic turret and coolant system

- Programmable tail stock body and quill

- Chain type chip conveyor and chip cart

OPTIONAL ACCESSORIES

Upgrade spindle nose taper from A2-8 to A2-11

Upgrade chuck diameter from 10” to (12” or 15”)

Upgrade spindle motor from 15/18.5 kW to 18.5/22 kW

Upgrade bar capacity from 75 mm to (90/105 mm)

Upgrade maximum turning length from 700 mm to (1200/1640/2200/3000 mm)

Upgrade to powered (live tools) turret APT-40

Bar feeder (various sizes available base on application)

Bar feeder interface (required for bar feeder option)

Upgrade to Fanuc 10.4” color LCD with Manual Guide

Renishaw HPRA tool setter

Renishaw HPPA tool setter

Oil mist collector

Oil coolant skimmer

Air conditioner for electrical cabinet

Transformer (440-460-480 to 220 volt)

On-site start up installation assistance

|

Specifications Model: |

KLR-300 |

|

Controller type |

Fanuc 0i-T |

|

Swing over bed |

612 mm (24.1”) |

|

Swing over saddle |

388 mm (15.3”) |

|

Maximum turning diameter |

500 mm (19.7”) |

|

Maximum turning length |

700 mm (27.6”) |

|

Bed slant angle |

30˚ |

|

Guide ways |

Box ways |

|

Spindle nose taper |

A2-8 |

|

Spindle hole diameter |

86 mm (3.38”) |

|

Power chuck diameter |

250 mm (10”) |

|

Spindle speed |

3500 rpm |

|

Spindle motor power (cont/30min) |

15/18.5 Kw (20/25 hp) |

|

Bar capacity |

75 mm (2.95”) |

|

Z-axis travel |

750 mm (29.5”) |

|

X-axis travel |

250+50 mm (9.8+1.9”) |

|

Z-axis rapid feed rate |

24 m/min (944 in/min) |

|

X-axis rapid feed rate |

20 m/min (787 in/min) |

|

Turret driven type |

Hydraulic |

|

Number of tool stations |

12 |

|

Square shank tooling size |

25 mm or 1” |

|

Round shank tooling size |

40 mm or 1.5” |

|

Tail stock body travel |

540 mm (21.2”) |

|

Quill travel |

120 mm (4.72”) |

|

Quill diameter |

85 mm (3.34”) |

|

Quill taper |

MT-5 |

|

Quill control type |

Hydraulic |

|

Tail stock body positioning |

Programmable |

|

Floor space |

3.0 x 1.8 m (119”x71”) |

|

Height |

1.8 m (71”) |

|

Weight |

5500 kg (12,130 lb) |

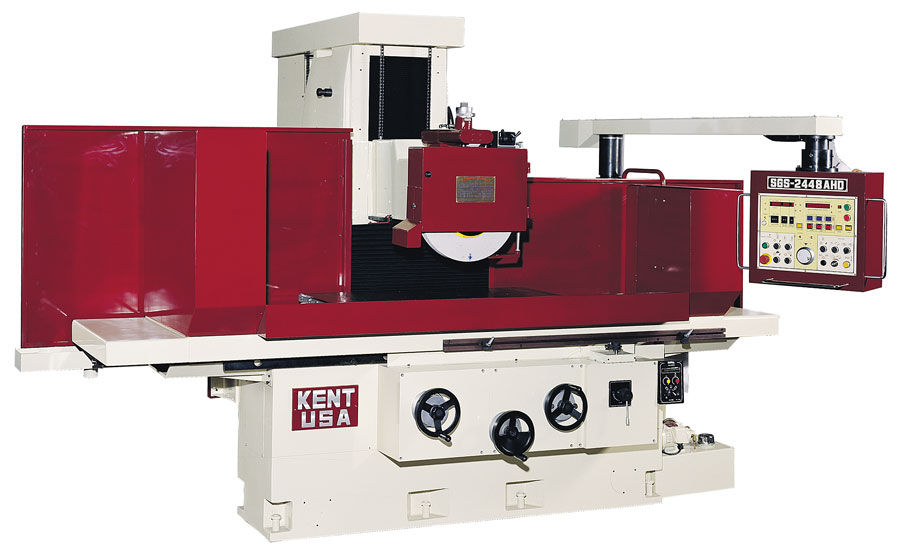

24" x 48" KENT USA SGS-2448 AHD AUTOMATIC SURFACE GRINDER - NEW

24" x 48" KENT USA SGS-2448 AHD AUTOMATIC SURFACE GRINDER - NEW  12" x 30" KENT USA SGS-1230 AHD AUTOMATIC SURFACE GRINDER - NEW

12" x 30" KENT USA SGS-1230 AHD AUTOMATIC SURFACE GRINDER - NEW  KENT USA WSI-530 CNC WIRE SUBMERGE TYPE EDM - NEW

KENT USA WSI-530 CNC WIRE SUBMERGE TYPE EDM - NEW  AMADA RG50 55 Ton x 6' CNC Press Brake

AMADA RG50 55 Ton x 6' CNC Press Brake