11″ x 18″ KENT USA CTL-618EVS PRECISION TOOLROOM LATHE – NEW

PRODUCT HIGHLIGHTS

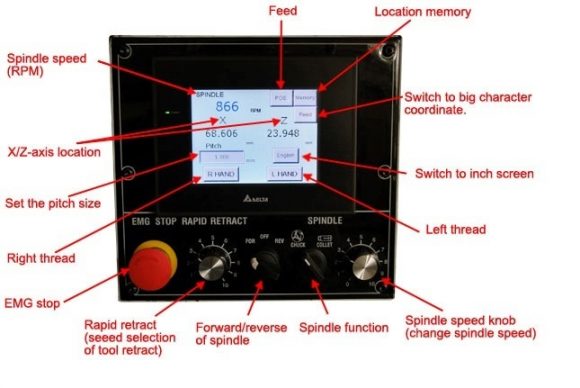

- 50-4000 infinitely variable spindle speeds using electronic vector drive

- Flat panel LCD display shows spindle RPM and tool feed rate to let operator easily select best turning conditions

- LCD displays electric current value to easily check for turning overload

- Rapid retract function shortens threading cycle

- Guaranteed Circular Accuracy to 0.00125mm

- Full bearing carriage with Turcite-B coated slide way bearing material between carriage and bed

- Fast lever collet chucking with one single movement

- Solid hardened and ground alloy tool steel bed

- Powerful 3 HP motor with current vector inverter drive increases low end torque

STANDARD ACCESSORIES

- 3-jaw chuck (6”)

- 5-C collet closer

- Coolant system

- Chip and coolant shield

- Back Plate

- Halogen work light

- Toolbox with standard tools

OPTIONAL ACCESSORIES

Tool setting gage

5C collet fixture plate (3-3/8” Dia)

5C collet fixture plate (4-3/8” Dia)

Vertical cut-off slide LB-68-11

Steady rest

Follow rest

Face plate

Taper turning attachment*

6” zero-set universal 3-jaw chuck with 4º back plate

6” 4-jaw chuck with 4º back plate

*DRO system integrated (2-axis)

6 station automatic indexing turret L-40T.

Indicator carriage stop T-CSD-618 (without indicator)

4 station turret T-AIT-06

Radius turning attachment T-RT-108

- Swing Over Bed

- Swing Over Cross Slide

- Swing Over Gap

- Width of Bed

- Distance Between Centers

- Cross Slide Travel

- Top Slide Travel

- Spindle Speeds

- Spindle Speed Range

- Through Hole Diameter

- Spindle Nose

- Spindle Bore Taper

- Thread – Standard (Whit-worth)

- Thread – Metric Pitch

- Longitudinal Feed

- Cross Feed

- Lead Screw Diameter

- Threading Pitch

- Quill Travel

- Quill Diameter

- Quill Bore Taper

- Main Motor

- Coolant Pump Motor

- Machine Dimension

- Packing Dimension

- Machine weight

- Packing weight

CTL-618E

- 11″

- 6″

- 9″

- 6-3/4″

- 18″

- 6″

- 3″

- Inf. Variable

- 50-4000 RPM

- –

- –

- I – 5C (10°)” & O – 4°

- Var (11-108) TPI

- Var (0.275-2.7) mm

- 5/16″ – 7″ ipm

- 5/16″ – 4″ ipm

- 1″

- 8 TPI

- 3.75″

- 1.358″

- MT#2

- 3 HP

- 1/4 HP

- 65″ x 28″ x 58″

- 85″ x 36″ x 68″

- 2300 LBS

- 2450 LBS

10" x 50" KENT USA KTM-4VKF-E MANUAL KNEE MILL - NEW

10" x 50" KENT USA KTM-4VKF-E MANUAL KNEE MILL - NEW  NAKAMURA TOME WT-300MMSY 8-AXIS CNC TURNING/MILLING CENTER

NAKAMURA TOME WT-300MMSY 8-AXIS CNC TURNING/MILLING CENTER  17" x 64" KENT USA TPR-2000H RADIAL ARM DRILL - NEW

17" x 64" KENT USA TPR-2000H RADIAL ARM DRILL - NEW